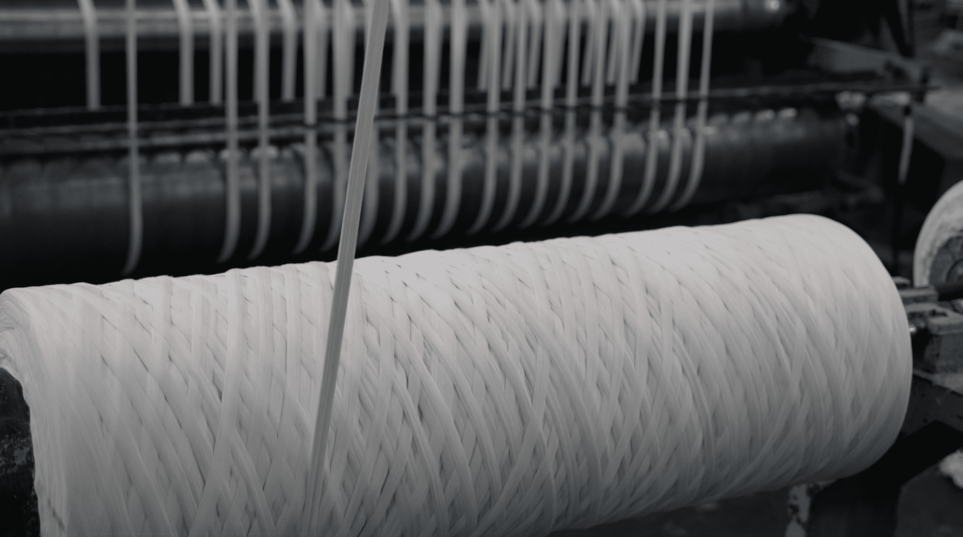

DNM, a leading denim manufacturer with operations in Egypt and a head office in Turkey, continues to strengthen its position through responsible production, advanced water and energy systems, and a growing global customer base. In this interview, Marketing Manager Firdevs Tekin shares shares insights into DNM’s sustainability practices, supply-chain structure, capacity expansion, certification standards, and the key product groups featured at the D&J Egypt show. Below is the full conversation, presented in a clear interview format for our readers.

Sustainability Measures & Environmental Impact

DNM publicly emphasizes ZLD wastewater treatment, energy-saving systems, and resource efficiency. Could you walk us through the key sustainability measures in place now, and any measurable impact, e.g. reduction in water, energy, or waste compared to conventional mills?

In conventional denim production, it is estimated that more than 80% of wastewater is discharged into the environment without adequate treatment. At DNM, we recognize that reducing water consumption and protecting natural water resources are essential responsibilities for our industry. For this reason, our facilities operate with a Zero Liquid Discharge (ZLD) system, ensuring that no industrial wastewater is released into the environment. All water used in production is fully treated on-site.

Today, 90.83% of our total water demand is supplied through recycled water, significantly reducing freshwater consumption and preventing environmental pollution. To track and continuously improve these efforts, we conduct annual water and carbon footprint measurements.

In addition to water stewardship, DNM is enhancing its environmental performance through new investments in renewable energy and efficient production technologies. Our solar energy system and thermal energy which captures and reuses waste heat support a more efficient energy model and contribute to lowering the overall impact of our operations.

Supply Chain, Logistics & Key Markets

With a factory in Egypt and head‐office in Turkey, how do you manage supply chain, shipping and logistics for global clients? Which markets (Europe, MENA, Americas) currently represent your biggest demand? Also please share your capacities for the purpose of our readers’ interest

We are able to serve our customers flexibly from both Egypt warehouse and İstanbul warehouse, depending on their specific needs. This dual-location structure allows us to optimize lead times, manage logistics more efficiently, and provide uninterrupted service across our global markets.

With the upcoming year-end capacity expansion, DNM will reach a monthly production capacity of 3.5 million meters. While we aim to grow across all our existing markets, our primary focus remains delivering consistent quality and sustainable service to our current customers.

Compliance, Certifications & Transparency

DNM holds multiple certifications and standards (GOTS, GRS, OEKO-TEX, HIGG, SEDEX, etc.). How important are these for your buyer base, and how do you manage compliance and audit transparency for clients looking for sustainable sourcing?

These certifications are highly important for our buyers, as they provide clear assurance of responsible and transparent production. With standards such as GOTS, GRS, OEKO-TEX, HIGG and SEDEX, we demonstrate full compliance in sustainability, safety and ethical manufacturing.

We manage this through regular audits, up-to-date documentation, and transparent reporting across both our Egypt mill and Turkey head office, ensuring our clients have full visibility whenever needed.

Fast Fashion & Delivery Pressure

Fast fashion is creating a lot of challenges for mills. How are you managing the pressure of meeting tight deliveries?

With the upcoming year-end capacity expansion, DNM will reach a monthly production capacity of 3.5 million meters. With this capacity increase, we will improve our delivery services.

Additionally, DNM has an optimization system in production processes; in this way we can manage our product range and production within the requested timeline.

Key Products for D&J Egypt Show?

While not on a product-specific basis, we can provide an overview of our product groups as outlined below:

BACK2K

A revival of early 2000s digital-era aesthetics with low-rise silhouettes, micro minis, and expressive textures. Faded blacks, dirty yellows, and rustic browns merge nostalgia with new direction.

NEO FUTURE

Where lightweight, flexible, breathable denim meets durability. Designed for modern travel and dynamic urban lifestyles.

SILENT CODE

Premium Tencel–linen blends, refined textures, and clean silhouettes that express timeless elegance and quiet sophistication.

SIGNATURE

A collection that bridges DNM’s heritage with modern interpretations. Classic silhouettes, unique wash effects, and elevated fiber compositions grounded in sustainable comfort.

Value-Added Services & Brand Support

Many mills now offer value-added services , wash houses, design collaborations, small-batch runs, and quick turnaround. Does DNM offer such services to clients, and how do you support brand partners beyond just delivering fabric?

Introducing our fabrics in the right fit and wash is extremely important to us. For this reason, DNM has an in-house R&D unit where we prepare our own garments and develop wash processes. This capability allows us to carry out tailored projects in line with our customers’ needs, providing dedicated support. In addition, we engage in design collaborations based on specific requests, further enhancing the quality of our service.

The interview reveals how the company remains committed to sustainability, Zero Liquid Discharge systems, innovative product groups, increased capacity, and value-added client services. Firdevs’s insights highlight DNM’s mission to shape the future of responsible and high-performance denim manufacturing.

Register here to attend Denimsandjeans Egypt Show.

Save Dates for Denimsandjeans (D&J) 2026

D&J Vietnam | D&J Egypt | D&J India | D&J Japan

The post DNM Interview: Sustainability, ZLD Systems, Capacity Expansion & 2025 Outlook appeared first on Denimandjeans.

DENIM and PATCHES sourced this post originally published on this site