This blog post is sponsored by Bluezone, the independent show for denim and sportswear by Munich Fabric Start. Register for the next show here!

Bluezone’s Keyhouse Is Where the Latest Tech and Craftsmanship Collide in the Future of Jeans

Denim enthusiasts know there’s magic in the old ways. Stiff raw denim, slubby yarns, and rope-dyed indigo all tie back to time-honoured traditions.

But do you know who—or what—is actually making your jeans? Robots and AI are shaking up denim production, but can they really replicate the human touch that we enthusiasts love so much?

At the Bluezone denim trade show by Munich Fabric Start, the future of denim takes centre stage. The technologies showcased at the upcoming January 2025 edition of the show will highlight just how much innovation is shaping the way jeans are made.

But innovation doesn’t have to mean the end of tradition. The real question isn’t whether technology is changing denim—it’s how it’s transforming the way jeans are made while staying true to their roots.

Where Denim Tech Is Already at Work

Technology is reshaping denim production in ways both subtle and revolutionary. But much of what we consider “traditional” denim is already shaped by modern tools that scale production, reduce costs, and improve sustainability—all while preserving the essence of authentic craftsmanship:

Indigo Dyeing

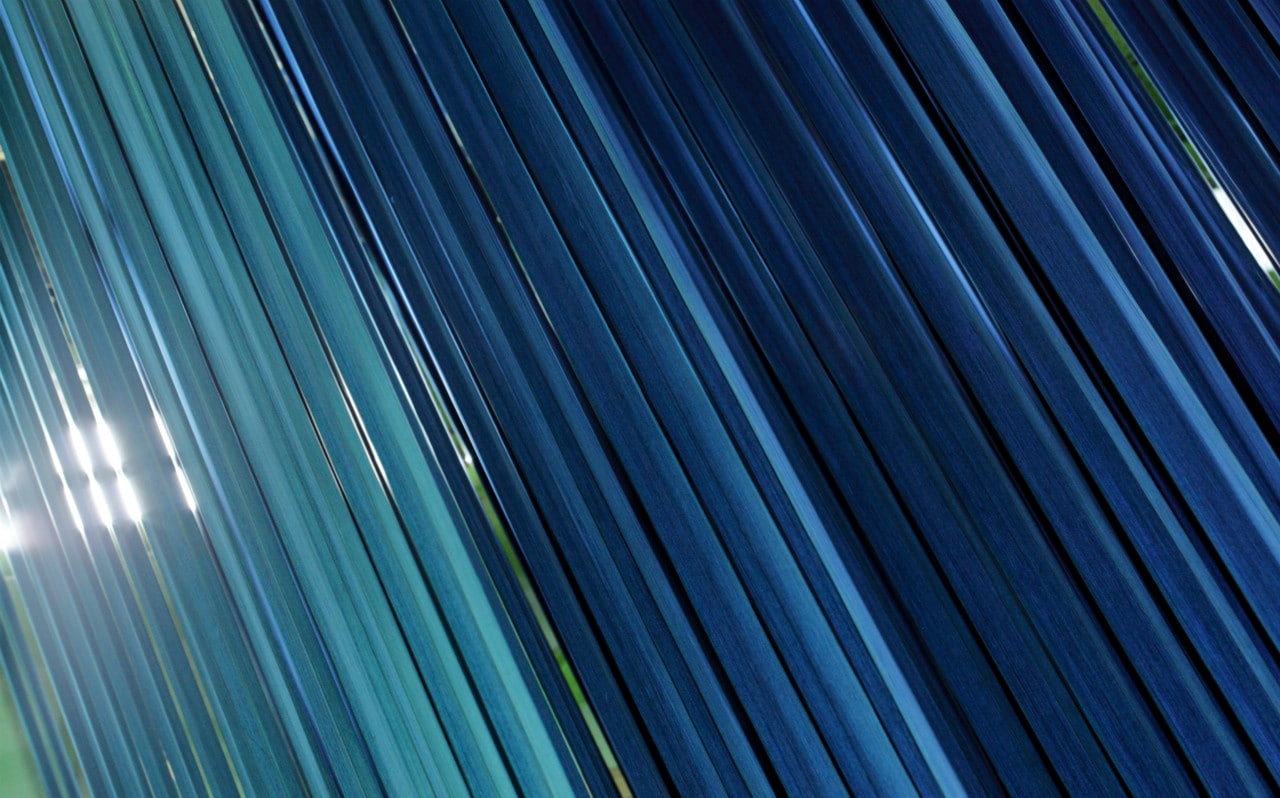

One area seeing rapid innovation is dyeing. Traditional rope dyeing has long been the hallmark of premium denim, but newer methods like foam and spray dyeing are changing the game.

These processes rely heavily on robotics for precision application, reducing water usage by up to 90% compared to older techniques. This not only conserves resources but also gives brands greater control over colour consistency—ensuring each pair of jeans comes out just right.

For more about how dyeing has evolved, check out our indigo guide.

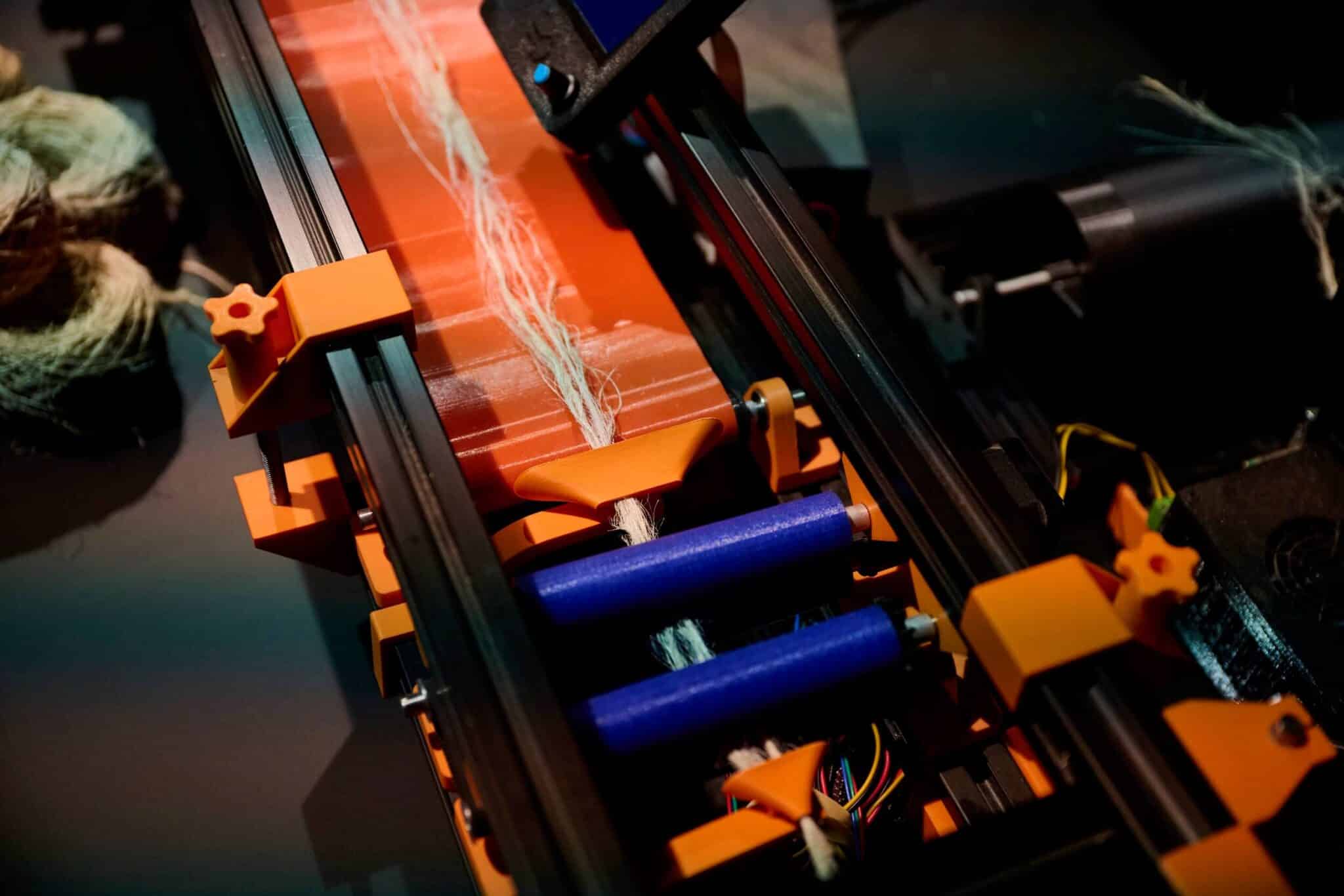

Spinning

In yarn spinning, traditional methods like ring spinning, which creates the slubby textures denim enthusiasts love, are combined with modern open-end spinning for speed and efficiency. Curious about the differences?

Learn more in our post on how denim is spun.

Weaving

There’s been a similar evolution in weaving.

While most denim today is made on shuttleless looms for scalability, the resurgence of shuttle looms for selvedge denim proves that quality craftsmanship remains in demand.

If you’ve ever wondered why selvedge denim is so prized, read about it in our post on how denim is woven.

Cut & Sew

In cutting and pattern placement, laser-guided machines bring incredible precision. These systems can slice through multiple layers of denim with minimal waste, ensuring every piece is perfectly cut.

Robotics are also making an impact in sewing operations, particularly for repetitive tasks like attaching belt loops or bartacking. Automation excels at these high-precision steps, freeing skilled workers to focus on more intricate details.

Finishes

Finishing processes have perhaps seen the most visible transformation.

Laser fading, for instance, replicates years of wear in mere minutes, creating intricate whiskers and fades without water or chemicals. Ozone treatments and enzyme washes deliver lived-in looks with minimal environmental impact.

If you’re curious about pre-washing, read more in our post on how jeans are pre-washed.

Where Humans Still Reign

Despite all the advances, denim still has its quirks—and robots and technology have their limits.

Flexible fabrics like denim are notoriously tricky for machines to handle, meaning many steps in the production process still rely heavily on human hands, such as:

Sewing

Take sewing intricate seams like chain-stitched hems.

These details, treasured by enthusiasts, are hard for robots to replicate because they require the dexterity and intuition of a skilled craftsperson.

Variations in denim thickness, stretch, or tension can throw off machines, while human hands instinctively adapt, ensuring that each stitch is just right.

QC

Quality control is yet another area where humans excel.

While AI can detect visible flaws, the touch and intuition of a skilled worker can pick up on issues—like inconsistent tension or subtle imperfections—that machines often overlook.

This hands-on approach ensures that every pair meets the standards enthusiasts expect from high-quality denim.

Dyeing

Even the art of indigo dyeing, while modernised in some areas, remains rooted in techniques that machines struggle to replicate authentically.

Rope dyeing, for example, requires an experienced operator to judge the timing of dips and drying, ensuring the perfect balance of deep indigo tones with a crisp white core. These subtle decisions, based on expertise rather than automation, preserve the magic of traditional indigo.

For all its advancements, technology still serves best as a complement to human skill, not a replacement. It’s the combination of artisan expertise and modern tools that keeps denim’s traditions alive while ensuring it can evolve for future generations.

A Glimpse at the Innovators Shaping Denim at Bluezone

The technologies shaping denim production today are already impressive. But they’re just the beginning.

At Bluezone, the Keyhouse sub-show is where tradition meets cutting edge. It’s become the beating heart of the event, drawing attention to the innovations and producers that are transforming the denim industry.

Among the many exhibitors at the show, these exhibitors exemplify the fusion of tradition, sustainability, and cutting-edge advancements that define the future of jeans:

Calik Denim

Calik Denim leads the charge with water-saving dyeing techniques and circularity-focused production. Their collections balance softness and durability, using recycled fibres and eco-conscious dyes to ensure their fabrics are as sustainable as they are stylish.

ISKO

ISKO’s Luxury by PG line redefines denim luxury by merging technical innovation with high-end aesthetics. Their commitment to sustainability and inclusivity ensures their designs deliver both beauty and responsibility.

Sharabati Denim

From the slubby textures of GOOD OLE to the biodegradable blends of RELIVE, Sharabati Denim showcases a diverse range of sustainable options. With bold prints in COOLR and elegant softness in VERSO, they prove that artistry and eco-consciousness can coexist beautifully.

Tejidos Royo

Tejidos Royo’s DRY SUN collection is a testament to the possibilities of innovation. Their DRY Colours technology eliminates wastewater while reducing water and energy consumption, delivering rustic yet modern fabrics crafted from natural fibres like linen and TENCEL .

.

General Trends Shaping Denim’s Future

Beyond these highlights, broader trends are reshaping how denim is made:

- Blockchain technology, for example, is providing greater transparency in the supply chain, allowing customers to trace their jeans back to their origins.

- Virtual design tools are reducing waste by digitising sampling, enabling producers to finalise designs without the need for physical prototypes.

For raw denim enthusiasts, it’s easy to feel apprehensive about the role of technology in denim’s future. But these innovations aren’t erasing what makes denim special—they’re preserving it.

The slubby textures, rich fades, and durable constructions that define raw denim are now being achieved more sustainably and efficiently.

Technology isn’t replacing heritage; it’s helping ensure that denim’s timeless appeal can thrive for generations to come.

Want to Know More About Denim’s Future?

Robots are taking on more and more of the heavy lifting in denim production, especially where speed, precision, and sustainability are concerned. But for now, the heart and soul of denim—the imperfect perfection—still belong to the skilled artisans who work alongside the machines.

Bluezone is where tradition and innovation collide—from the latest technologies at Keyhouse to the broader trends shaping the denim industry. Whether it’s robots, AI, or sustainable practices, this show and its exhibitors are driving these changes.

The post Craft and Code: Exploring the Future of Jeans at Bluezone appeared first on Denimhunters.

DENIM and PATCHES sourced this post originally published on this site